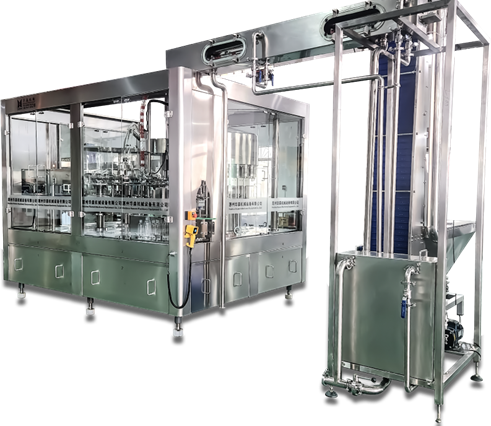

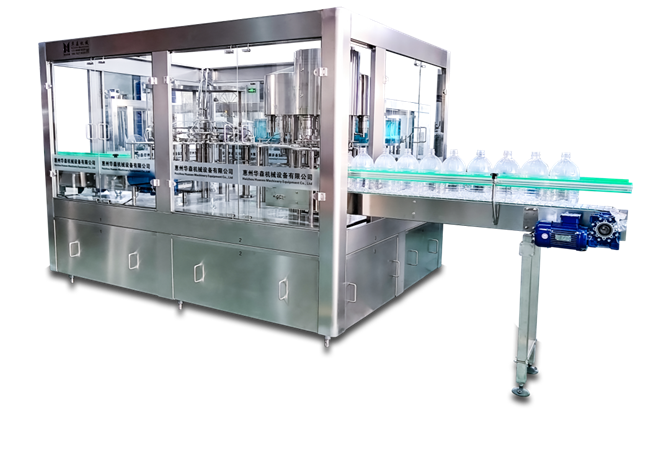

Products Description

Vital for maintaining hygiene in recycling lines, this machine guarantees meticulous cleaning and disinfection of empty buckets, which is essential for ensuring the quality of barreled water. The cleaning process is optimized for ease of control and reliable operation. Backed by our extensive experience in research, development, and manufacturing, we have crafted comprehensive designs tailored to meet the specific process requirements of our customers. The entire equipment control system is powered by Siemens PLC, and features electrical switches from Schneider, frequency converters from Danfoss, clean switches from Omron and Leuze, cylinders from AirTac, and photoelectric devices from Omron and Autonics. This ensures the stability and smooth operation of the equipment.

Model | HSXZG-6-900 | HSXZG-8-1200 | HSXZG-10-1500 | HSXZG-12-2000 |

Rows and adjustable stations | 6 rows and 16 stations | 8 rows and 16 stations | 10 rows and 18 stations | 12 rows and 18 stations |

Barrel Specifications | F270*490(mm) | F270*490(mm) | F270*490(mm) | F270*490(mm) |

Flushing capacity (barrels/h) | 900 | 1200 | 1500 | 2000 |

Air pressure | 0.6Mpa-0.8Mpa | 0.6Mpa-0.8Mpa | 0.6Mpa-0.8Mpa | 0.6Mpa-0.8Mpa |

Air consumption | 0.7m3/min | 0.8m3/min | 0.9m3/min | 0.9m3/min |

Rated voltage | AC380/50Hz | AC380/50Hz | AC380/50Hz | AC380/50Hz |

Tags: